Unlock the Pure Potential of Your Flower

In today’s uncertain times, it’s more critical than ever for growers to safeguard their investments and stand out in a competitive market. For growers striving not only to regain their footing and recoup initial investments but also to differentiate their products and command higher prices per pound, our advanced sterilization, rehydration, and infusion processes offer a transformative edge. We empower you to elevate every bud into a unique, premium product that secures a competitive advantage and unlocks hidden value in your harvest.

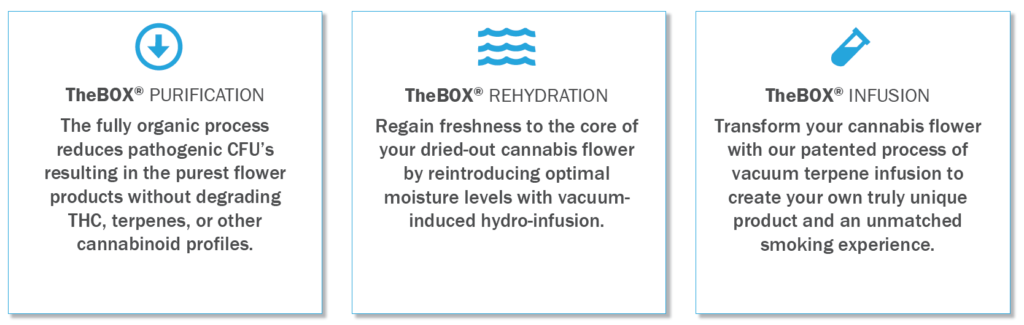

How It Works:

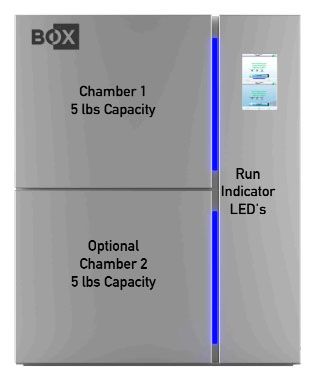

Experience a new level of quality control for your cannabis or hemp flower with TheBOX®—a patented, organic, and powerful vacuum-induced sterilization system that harnesses our proprietary Reactive Oxygen (rO). Every run is a complete cycle designed to:

Sterilize and Purify:

Remove contaminants and neutralize harmful pathogens at the DNA level without compromising cannabinoids (THC, CBD) or terpene profiles. This critical first step prepares your flower to fully benefit from the subsequent processes.

-You can choose to stop here and enjoy a significantly cleaner product, or continue to the next step for even more benefits.Rehydrate:

Precisely optimize moisture levels in dried flower, restoring the perfect hydration balance to enhance texture and overall quality.

-Opt to conclude your process at this stage for optimally rehydrated buds, or proceed further to add a layer of customized flavor and aroma.Infuse:

Seamlessly introduce original native terpenes to create customized flavor and aroma profiles—a revolutionary step on one side of the Infusion coin that is part of a broader infusion revolution sweeping the country.

-This final step is available if you’re ready to transform your product into a truly distinctive market leader, though you’re free to stop after purification or rehydration if that meets your goals.

TheBOX®’s comprehensive, full-spectrum decontamination process not only protects your brand by ensuring cleaner, safer products but also drives a total infusion revolution. By integrating these three critical steps—whether individually or in combination—you unlock hidden value in your harvest, ensuring every bud reaches its truest potential while giving you complete control over the transformation process.